From Field to Fabric

UGA researchers innovate to secure the future of Southern cotton

Do you know where your T-shirt got its start? In this episode of Cultivating Curiosity, we travel to Tifton, Georgia, to speak with Camp Hand (pictured at right), assistant professor in the CAES Department of Crop and Soil Sciences and a key member of the UGA Cotton Team. Join us as we dive into the intricacies of cotton agronomy, the importance of UGA's experiment stations and the collaborative nature of the cotton industry in Georgia.

Imagine a plant so valuable it helped shape the course of human civilization — a plant that has stitched together empires, economies and entire ways of life.

That plant is cotton.

Long before industrialization, societies in the Indus Valley, ancient Egypt and pre-Columbian Peru cultivated cotton for its durable fiber. In North America, Indigenous peoples had been growing and using cotton for centuries before European contact. Archaeological discoveries — including roasted cottonseed fragments in Arizona dating back 1,400 years — reveal cotton’s role in Native cultures.

This tunic was woven sometime between 500-850 CE by Moche artisan(s) of Peru. The garment blends cotton and camelid hair in intricate patterns. (Photo courtesy of The Metropolitan Museum of Art.)

This tunic was woven sometime between 500-850 CE by Moche artisan(s) of Peru. The garment blends cotton and camelid hair in intricate patterns. (Photo courtesy of The Metropolitan Museum of Art.)

It’s a plant with remarkable staying power. Cotton remains one of the most widely used textile fibers in the world. In Georgia alone, cotton covers 1.1 million acres and continues to be the state’s top-grossing row crop, with a 2022 farm gate value of $1.31 billion. But its influence stretches far beyond clothing.

“What makes cotton especially interesting, even among major crops, is its dual purpose,” said Camp Hand, a cotton agronomist for University of Georgia Cooperative Extension and a faculty member in the College of Agricultural and Environmental Sciences. “It’s both fiber and food.”

While best known for its fiber, cottonseed and cottonseed oil are used in animal feed and, in small quantities, in food products for human consumption.

A member of the Malvaceae family — like okra and hibiscus — cotton has both wild and domesticated forms. While wild cotton grows as a woody perennial, cultivated cotton is grown as an annual. Of the 39 known cotton species, only four produce commercial lint. In the U.S., farmers grow just two: upland cotton (Gossypium hirsutum) and Pima cotton (G. barbadense), explained Hand, who earned his doctorate in crop and soil sciences at CAES in 2021.

But more than a crop, cotton is a living thread that ties the past to the present.

Two women operate a small cotton gin, circa 1900s. (Photo courtesy of The New York Public Library)

Two women operate a small cotton gin, circa 1900s. (Photo courtesy of The New York Public Library)

Cotton’s rise in the South

Cotton has long been woven into the story of the American South, not only as a cultural symbol but also as an economic powerhouse. Georgia played an early role in that transformation. The state’s first recorded cotton crop was planted in 1733 in the Trustees’ Garden in Savannah.

The true turning point came in 1793, when schoolteacher Eli Whitney invented the cotton gin, a hand-cranked machine that dramatically sped up the tedious process of separating fiber from seed. With Whitney’s invention, one worker could process 50 pounds of cotton a day — compared to just 1 pound by hand. Cotton, once seen as too labor-intensive to be profitable, suddenly became a booming cash crop.

“What the cotton gin did was introduce a scale of efficiency that shifted everything,” said Sha’Mira Covington, assistant professor of fashion in the University of Georgia’s Department of Textiles, Merchandising and Interiors. “It redefined what was possible for textile production, not only in the U.S. but around the world, and was one of the first crops that really laid the foundation for globalization.”

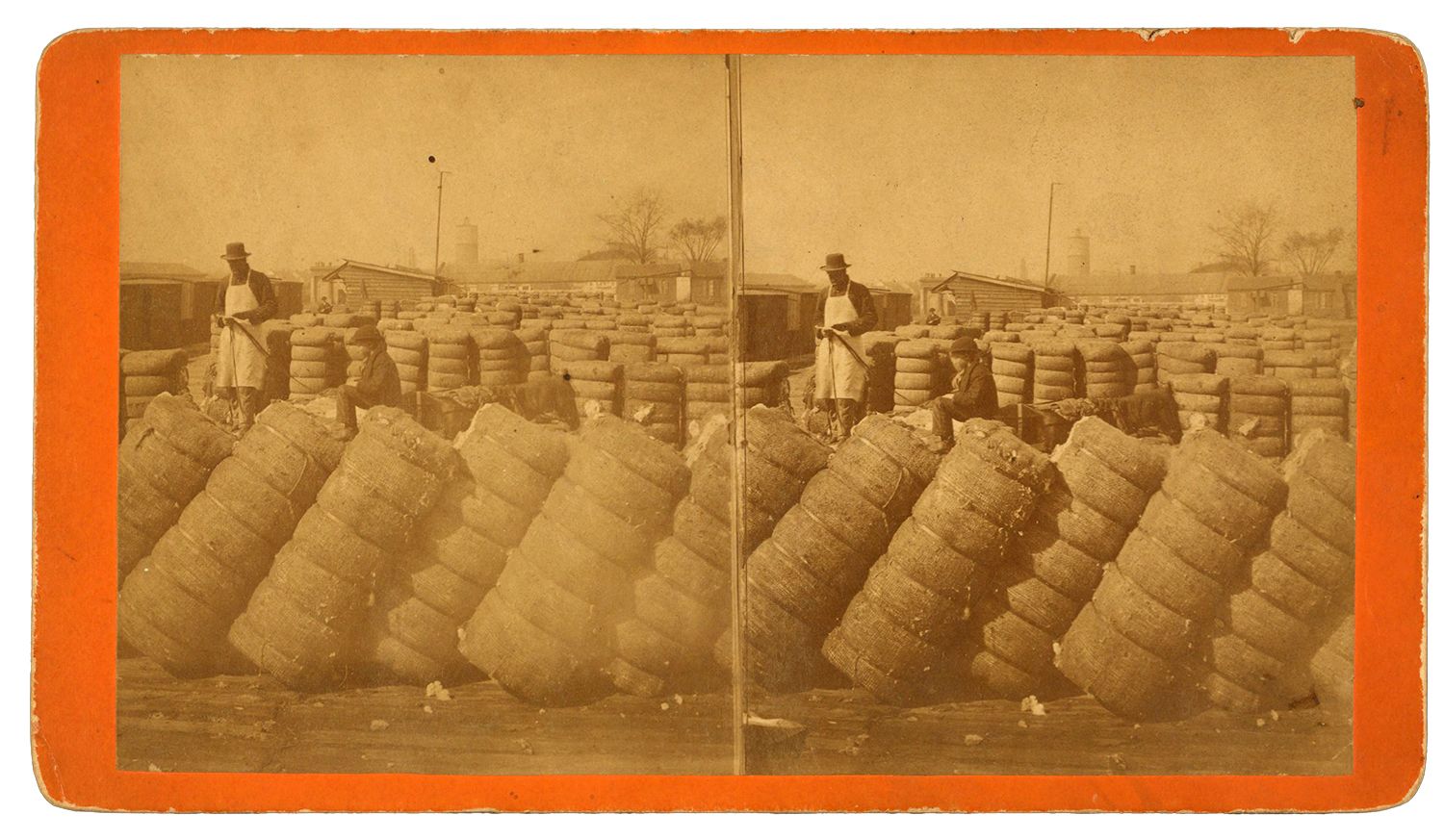

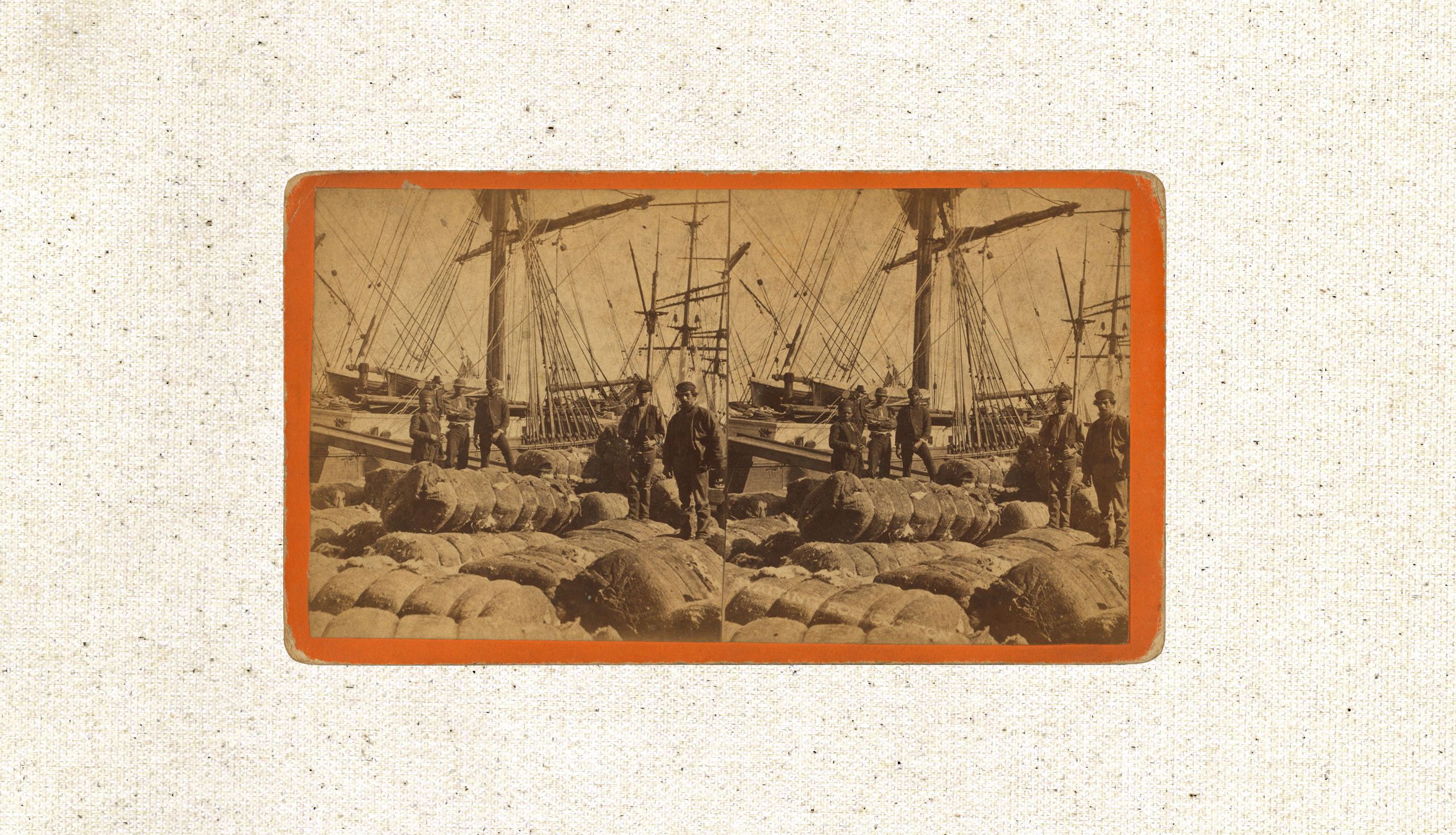

Stereogram depicting cotton bales awaiting shipment by railroad in Augusta, Georgia, sometime between 1870-1900. (Photo by John Usher. Courtesy of The New York Public Library)

Stereogram depicting cotton bales awaiting shipment by railroad in Augusta, Georgia, sometime between 1870-1900. (Photo by John Usher. Courtesy of The New York Public Library)

However, Covington noted the crop’s profitability depended on intensive labor, from planting to harvesting and ginning, and Southern plantation owners turned to a system already used in the region: slavery. As cotton demand surged, so did the reliance on enslaved African laborers. By 1850, nearly 2 million enslaved people lived in Georgia alone, and the Southern U.S. produced more than three-quarters of the world’s cotton, feeding British textile mills and anchoring transatlantic trade.

The cotton grown across most of the South was upland cotton, a high-yielding, versatile variety native to Central America that thrives in the region’s inland soils. But this widespread reliance on a single variety created the perfect conditions for disaster.

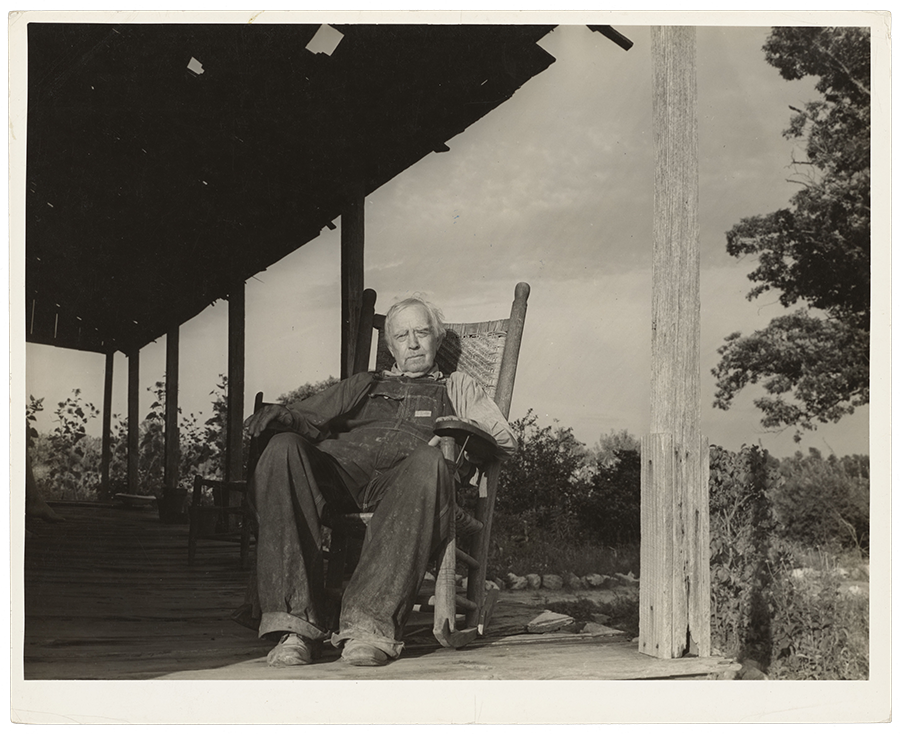

A cotton farmer in Greene County, Georgia, sits on his porch in July 1937. The land he inherited is now heavily mortgaged. (Photo by Dorothea Lange. Courtesy of The New York Public Library)

A cotton farmer in Greene County, Georgia, sits on his porch in July 1937. The land he inherited is now heavily mortgaged. (Photo by Dorothea Lange. Courtesy of The New York Public Library)

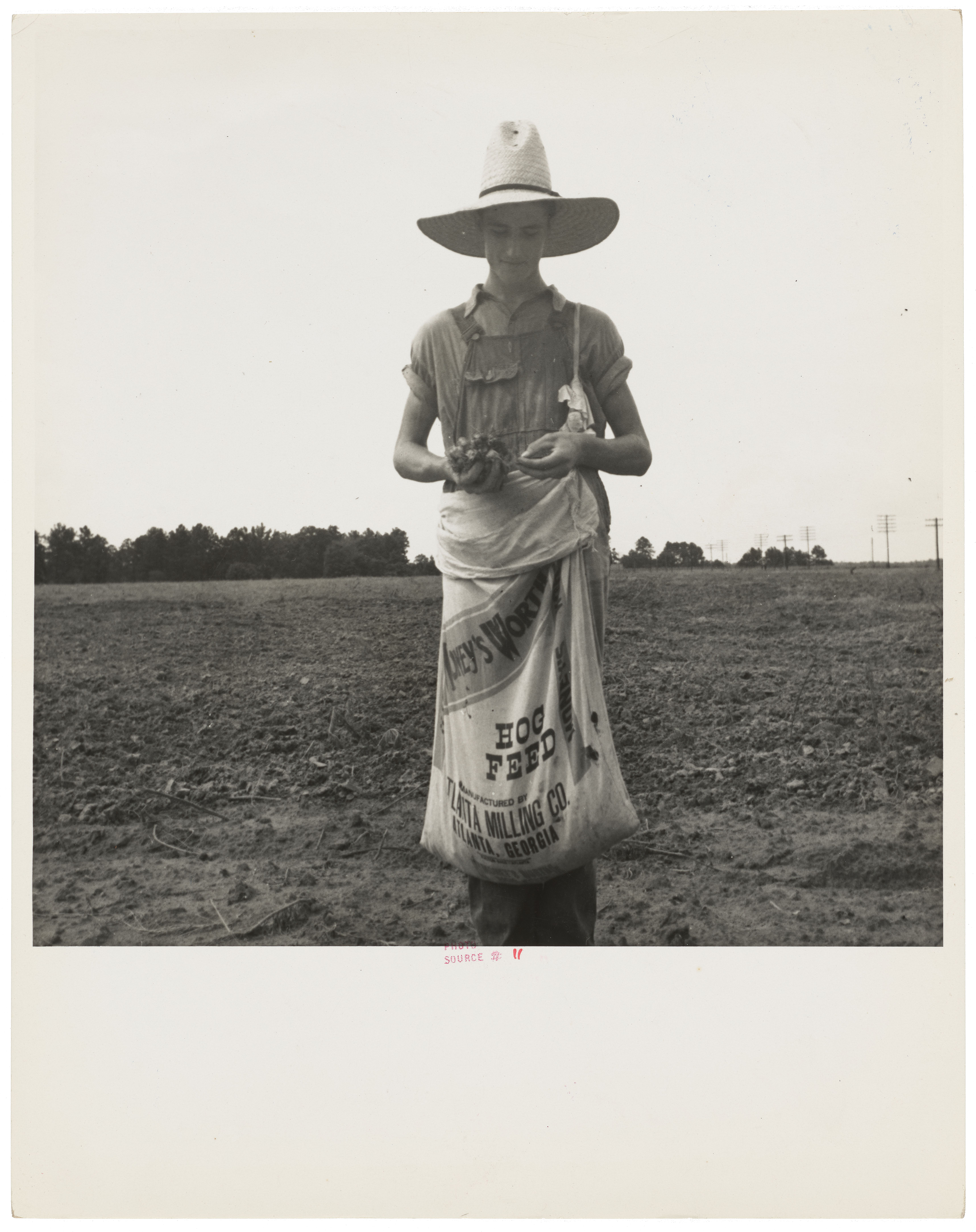

A boy holds a sack of boll weevils he picked off cotton plants in Macon County, Georgia, July 1937. (Photo by Dorothea Lange. Courtesy of The New York Public Library)

A boy holds a sack of boll weevils he picked off cotton plants in Macon County, Georgia, July 1937. (Photo by Dorothea Lange. Courtesy of The New York Public Library)

A new threat, a new response

Just as cotton seemed unstoppable in the early 20th century, Georgia’s cotton industry suffered a dramatic collapse when a tiny, destructive insect called the boll weevil (Anthonomus grandis) migrated from Mexico to Texas and spread rapidly throughout the Cotton Belt in the southern states. Feeding only on cotton, it devastated rural economies and exposed the risks of monoculture.

At its peak in 1914, Georgia planted more than 5 million acres of cotton, said Phillip Roberts, a UGA Extension entomologist. First detected in Georgia in 1915, the arrival of the boll weevil triggered a rapid decline in production across the state. By 1923, production fell from 2.8 million bales to just 600,000 as many farmers abandoned cotton.

Roberts said the boll weevil truly reshaped the way researchers and growers think about agriculture, ushering in a new era of stewardship, science and support that continues to guide cotton production in Georgia and across the South.

“When I think back to where we were and where we are now, it’s hard to believe,” Roberts said. “The boll weevil forced us to become better stewards of the land and better thinkers in the field.”

A boll weevil crawls along a cotton boll. (Photo by Clemson University - USDA Cooperative Extension Slide Series, / Bugwood.org / CC-BY-3.0-US)

A boll weevil crawls along a cotton boll. (Photo by Clemson University - USDA Cooperative Extension Slide Series, / Bugwood.org / CC-BY-3.0-US)

Constant adaptation is key

Cotton is Georgia’s top row crop, and the state ranks second in national production, but growing it requires more hands-on attention than corn, soybeans or vegetables.

“There’s always something new to learn,” said John Snider, a crop physiology professor in the Department of Crop and Soil Sciences and recipient of the 2023 D.W. Brooks Award for Excellence in Research. “It’s a crop that never gives you the same season twice.”

Snider’s research focuses on understanding how seed traits such as seedling vigor and stress tolerance affect cotton’s ability to thrive under variable field conditions, and how these traits interact with environmental stressors like drought, nutrient availability and temperature fluctuations to uncover biological weak points that limit productivity.

By pinpointing how cotton responds to stress in early development, Snider’s work helps identify which traits breeders and growers should prioritize. “When producers have a better grasp of what’s happening inside the seed, they can make more strategic decisions to support uniform emergence and healthier plants across the season,” he said.

Cotton physiologist John Snider measures the rate of photosynthesis in cotton plants at the University of Georgia's Tifton campus. (Photo by Paul Privette)

Cotton physiologist John Snider measures the rate of photosynthesis in cotton plants at the University of Georgia's Tifton campus. (Photo by Paul Privette)

Cotton is Georgia’s top row crop, and the state ranks second in national production, but growing it requires more hands-on attention than corn, soybeans or vegetables.

Precision agriculture specialist Wes Porter holds a custom-built soil moisture sensor probe that is used in irrigation trials to monitor soil moisture at three different depths. (Photo by Paul Privette)

Precision agriculture specialist Wes Porter holds a custom-built soil moisture sensor probe that is used in irrigation trials to monitor soil moisture at three different depths. (Photo by Paul Privette)

Smart tools for smarter yields

Research findings like these inform better, more accurate production management techniques, said Wes Porter, a UGA Extension precision agriculture specialist and agricultural engineer.

Porter’s work bridges research and on-farm decision-making, helping growers improve efficiency and sustainability. His program focuses on integrating precision agriculture technologies — from variable-rate planting to sensor-based irrigation — into every stage of cotton production. At planting, precision is critical, as cotton’s tiny seeds are notoriously finicky in Georgia’s clay-based soils.

Beyond planting, Porter’s expertise in machinery systems, soil compaction and irrigation scheduling helps farmers fine-tune their entire production system. His research supports everything from improving fertilizer application accuracy to enhancing water use efficiency with drip and pivot systems tailored to Georgia’s diverse soils.

Cotton and conservation

At UGA’s Southeast Research and Education Center (REC) in Midville, Superintendent Anthony Black has been helping farmers meet the challenge of producing sustainable cotton since 2008.

“Nothing ever stays the same in agriculture,” said Black, a 1998 CAES graduate in crop and soil sciences. “We’re always adapting — whether it’s to resistant weeds, changing climate patterns or market demands. That’s why these research stations are so important.”

One major shift during Black’s tenure has been an increased focus on reduced tillage and the use of cover crops between rotations. These practices improve soil health, reduce erosion, and lower fuel and labor costs. They also enhance cotton’s potential to play a role in climate solutions.

“When grown with conservation practices like cover cropping and no-till, cotton can pull more carbon dioxide from the air than it emits,” explained Porter. “It is one of the few crops with true carbon sink potential.”

Cotton blooms at J. Phil Campbell Research and Education Center in Watkinsville, Georgia. (Photo by Sean Montgomery)

Cotton blooms at J. Phil Campbell Research and Education Center in Watkinsville, Georgia. (Photo by Sean Montgomery)

Every drop counts

Perhaps the most pressing issue Porter and Snider address together is water management. Cotton is drought-tolerant compared to some crops, but precise irrigation is still essential for optimal yield — and responsible water use is under intense scrutiny in Georgia, where water disputes with neighboring states remain a political and environmental concern. Though Georgia won a major legal battle, conservation practices must continue.

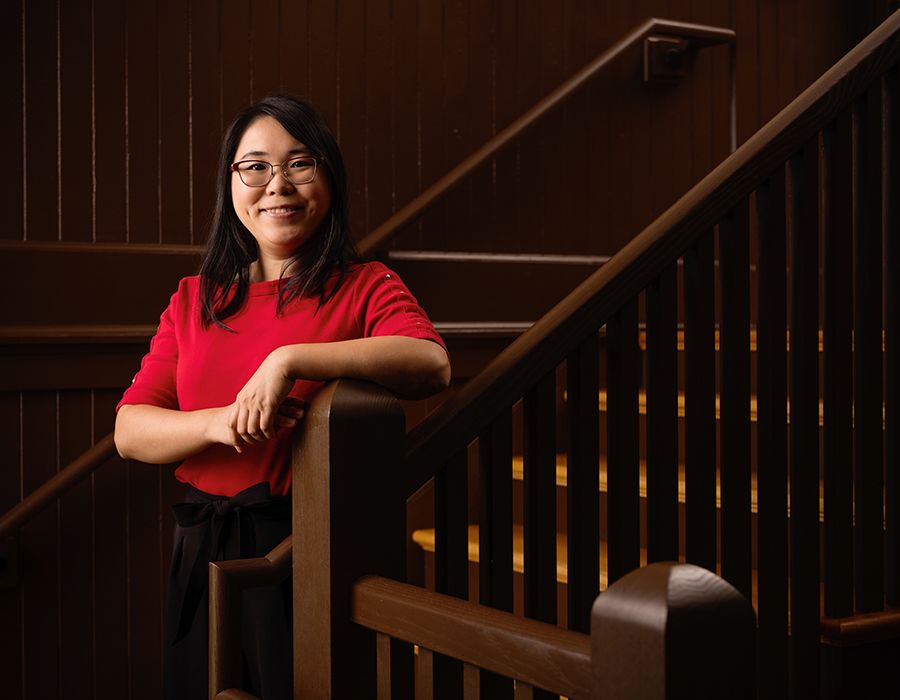

Cotton economist Yangxuan Liu poses in the historic H.H. Tift building on the UGA-Tifton campus. (Photo by Paul Privette)

Cotton economist Yangxuan Liu poses in the historic H.H. Tift building on the UGA-Tifton campus. (Photo by Paul Privette)

To address the root cause of the decades-long legal battles, Porter and Snider, along with CAES cotton economist Yangxuan Liu and precision agriculture engineer George Vellidis, are building a dynamic growth model that evolves with the cotton plant over the season. Supported by a $750,000 grant from the Foundation for Food and Agriculture Research, the model will combine physiological data with weather forecasts and decades of field trials to predict a cotton plant’s water needs with remarkable accuracy, saving resources.

“If we know what optimal growth looks like and how it changes with the weather, we can start predicting when the plant will need water, not just based on sensors or forecasts, but based on the plant itself,” Snider said.

Machine learning for better bolls

Snider’s research lays the groundwork for improving cotton genetics, dovetailing closely with that of UGA cotton breeder Peng Chee, whose mission is to develop high-performing cotton with genetics tailored to the Southeast.

While Snider investigates how specific traits influence plant performance under stress, breeders like Chee must sift through thousands of potential genetic combinations to find the few that consistently deliver results in the field. But screening for physiological traits like heat tolerance or photosynthetic efficiency is often slow and labor-intensive — a bottleneck for breeding progress.

With support from a $795,000 grant from the U.S. Department of Agriculture’s National Institute for Food and Agriculture, Snider will develop machine learning tools that can select key plant traits for heat tolerance in upland cotton, enabling researchers to evaluate hundreds of plants in seconds rather than hours.

Cotton for a changing world

Chee has spent more than 25 years leading cotton breeding efforts at UGA to develop elite germplasm adapted to Georgia’s growing conditions. These lines serve as the genetic foundation for commercial seed companies to build market-ready varieties.

While the result is improved seed, the process is meticulous and long term. It begins with selecting parent plants that carry desirable traits, crossing them to create hybrids, and then self-pollinating those hybrids over four to five generations to stabilize their genetics. Only then can researchers begin testing for yield, fiber quality and disease resistance — a process that can take another four or more years. It can take more than a decade to release a new variety.

To speed this up, Chee uses tools like DNA markers to screen plants for desirable traits early in the process, long before they’re grown in field trials. These markers act like shortcuts, helping breeders focus on the most promising lines.

“Think about bed sheets — the feel of a basic 300-thread-count sheet versus a premium 700-thread-count sheet comes down to fiber quality,” Chee said.

Unlocking cotton’s genetic potential

Cotton’s genetic history adds to the challenge. Of the four domesticated cotton species, Gossypium hirsutum — upland cotton — makes up 96% of global production. Today’s varieties trace to a limited genetic pool brought from Central America to the Southern U.S. in the 1700s. After two centuries of selective breeding, upland cotton is well adapted to U.S. conditions, but its genetic base has narrowed.

That’s why Chee and his collaborators are working to reintegrate genes that were left behind — what they call exotic genes. In their publication, “Exotic Genes May Improve Cotton Yield and Quality,” they show how these previously overlooked genes can provide valuable traits when reintroduced using both genomics and traditional breeding. “We’re once again understanding that diversity is the fuel of genetic progress,” Chee said.

An ethical alternative to fast fashion

Despite the dedicated, steadfast innovation in cotton production, the biggest competitor for the natural fiber is synthetic fibers made from fossil fuels, which dominate the fast fashion industry.

Covington, whose research in FACS explores the cultural, historical, social and political significance of fashion and dress, said sustainable fashion requires more than better materials — it requires a shift in thinking.

“We don’t need more ‘good’ clothes, we need fewer clothes that we actually wear,” she said. That mindset shift means moving toward curated wardrobes.

“Better quality means longer-lasting garments,” said Zeke Chapman, owner of Magnolia Loom, a T-shirt company that uses 100% USA-grown and -sewn cotton garments, including cotton grown at UGA’s Southeast REC. “And that’s where the real value lies.”

The rise of fast fashion has not only flooded the market with disposable synthetic clothing, it has also exposed the human cost of cheap labor and opaque supply chains. Programs like the U.S. Cotton Trust Protocol exist in direct response to these concerns, offering accountability in an industry where fair treatment of workers and environmental care are often sacrificed for speed and profit.

The Trust Protocol and its Climate Smart Cotton Program® help U.S. growers document their practices, ensuring that cotton is grown using sustainable methods and processed under ethical labor conditions.

Cotton has shaped the South for centuries — but today, the landscape is shifting under the weight of global economics, rising input costs, climate disruptions and changing consumer expectations. Amid these pressures, Georgia’s cotton growers are finding resilience through research, innovation and a renewed commitment to sustainability — guided in large part by the UGA’s Cotton Team.

Scenes from the UGA Cotton Microgin, a research-focused facility that mimics the work of a commercial gin on a smaller scale. The microgin handles cotton from small test plots, giving researchers precise data to advance Georgia’s cotton varieties. (Video by Anthony Barkdoll)